Welding specifications

In the following some considerations about the welding prescriptions are reported as per Eurocode norm.

The aim is to offer to the designers a summary of the main specifications that need for a definition of a welding process such as: classification of welding, prescription for drawings, criteria for selection, certification, needed checks, etc…

The applicable European norms for the welding are specified by the following main documents:

EN 1993-1-8

EN ISO 5817:2008

EN 1090-2:2014

EN 1090-3:2008

EN 12062:2004

Classification of the welding

The welding is classified considering the admissible levels of defeats that it can have during the manufacturing process.

It is engineer responsibility to select the appropriate admissible level taking into account the importance of the welded piece and its destination.

The Eurocode 3 (UNI EN 1993-1-8 §4.1(3)) specifies that all the welding should have a level C of defeat as per EN ISO 25817. Anyway this norm has been substituted by the EN ISO 5817:2014 that defines 3 admissible levels of defeats, that are, starting from the worst level to the best:

- Defeat level of quality D

- Defeat level of quality C

- Defeat level of quality B

For information, from the Italian norm NTC2008 (§ 11.3.4.5), the acceptable minimum level is the quality C for standard welding and B for welding subjected to fatigue.

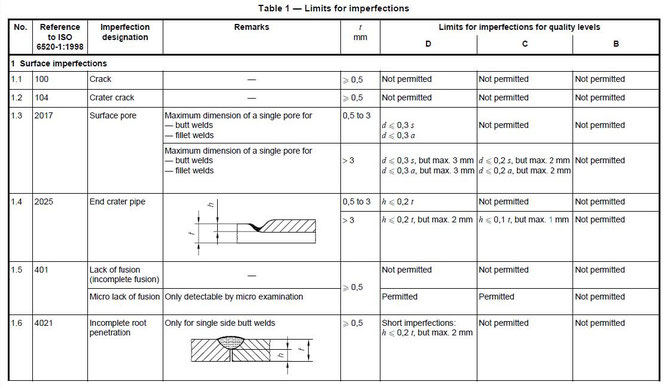

The following table is an extract from the EN ISO 5817 and shows an example of the acceptable defeats in the weld for the different quality levels.

See the EN ISO 5817 for the complete list of the cases.

The norm EN 1090 (EN 1090-2:2011 for steels and EN 1090-3:2008 for aluminum) is more detailed and links the defeat level to the execution class EXC.

Four classes are defined and they are equivalent to the defeat levels (cfr. §7.6) as in the folowing, starting from the worst level to the best:

-

Execution class EXC1

>> quality defeat

level D (as per EN ISO 5817)

-

Execution class EXC2 >>

quality defeat

level C (as per EN ISO 5817) with some exceptions reported in the norm;

-

Execution class EXC3 >>

quality defeat level B (as per EN ISO 5817);

-

Execution class EXC4 >>

quality defeat level B (as per EN ISO 5817) with additional restrictive requirements reported in the

norm.

From the EN 1090, execution classes may apply to the whole structure or to a part of the structure or to specific

details.

A structure can include several execution classes. A detail or group of details will normally be ascribed one execution class. However, the choice of an execution class does not necessarily have to be the same for all the requirements.

From EN 1090 if no execution class is specified the EXC2 shall apply.

The list of requirements related to execution classes is given in A.3.